Have you ever wondered how a genuine medieval armour is made? We’re not talking about mass-produced replicas, but pieces forged with the same skill and dedication as centuries ago. In the heart of Olías del Rey, near Toledo, the company Marto keeps this tradition alive, transforming Toledo steel into armours that are true works of art. Get ready to discover the fascinating artisanal process that turns a simple metal sheet into a stunning armour, worthy of a king.

Armour is a garment composed of metal or other resistant material (such as leather) pieces that was used to protect the body of the combatant. A full suit of armour consists of numerous articulated sections, with as many as 250 pieces assembled on a single fighter, weighing around 25 to 30 kg. However, the most common and important sets are around 25 pieces, distributed among the four groups: head, torso, and upper and lower limbs.

A Legacy of Centuries in Every Hammer Blow

Marto is not just a manufacturer; it is a guardian of history. Their armours, which often replicate those from prestigious collections such as that of Charles V in the Royal Armoury in Madrid (14th and 15th centuries), are considered unique products worldwide. Imagine the dedication required to create a piece that can weigh between 15 and 25 kg, entirely by hand, just as it was done hundreds of years ago.

Complete Tournament Black Armour, ready to assemble. Made of satin steel. Includes supports, stand, lance, shield, and full set of armour.

The Journey of Steel: From Flat Sheet to Masterpiece

It all starts with the raw material: a flat steel sheet. This is where the skills of Marto’s craftsmen, like Antonio and Carlos (father and son), come into play. Think of it like tailoring a dress, but with metal: templates are used to cut each individual piece of the armour. This is the first step, crucial for the final shape each component will take.

Once cut, the flat pieces move to the shaping phase. This process requires unmatched precision and skill. With the hammer as the main tool, and the expert hands of the craftsman, each piece begins to take on volume and curve. It’s a laborious and repetitive job, where every strike counts for shaping the metal.

After the initial shaping, the focus shifts to refining and finishing. Small bumps and imperfections that may have arisen during forging are carefully eliminated until the piece is completely smooth. Each component of the armour is unique and is treated differently: some pieces are welded together, while others are “bordered” to join them securely and with an impeccable aesthetic. How long can this whole process take? Surprisingly, a complete armour can take about a week to be finished.

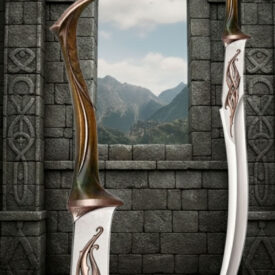

Complete Tournament Ristre Armour ready to assemble. Made of steel. Includes supports, stand, lance, and the full set of armour.

Ancestral Tools and Details That Tell Stories

For certain pieces, such as those requiring very specific shapes, craftsmen use unique tools. One example is a log of wood with various grooves, perfect for working on curved parts like the chin of a helmet. This demonstrates how experience and adaptation of traditional tools are key in this craft.

But the beauty of an armour lies not just in its shape, but also in its decorative details. This is where a very special ancient technique comes into play: embossing. Craftsmen like Jaime devote themselves to “embellishing” the armours. How do they do it? Starting from a smooth piece, they manage to create designs and reliefs by making the metal bulge from the back. Then, from the front, these designs are shaded and defined using small taps. It’s an incredibly laborious process, but the result is pieces with impressive visual richness.

Safeguarding a Fading Art

The embossing technique, like much of the handcrafted armour-making process, is an ancestral skill that fewer and fewer people master. Marto, with its commitment and knowledge passed down from generation to generation (as in the case of Antonio and Carlos), actively seeks to ensure that these artisanal crafts are not lost.

An armour from Marto is not just an object. It is the result of hours of manual work, the application of centuries-old techniques, and the passion of craftsmen who devote their lives to preserving a unique trade. Each piece is “perfectly finished and ready for use”, ready to be admired and, if the occasion arises, for battle! When you choose one of these Marto armours, you are not only acquiring a piece of metal, but a piece of history forged with the heart of Toledo steel. A true treasure that demonstrates that tradition and craftsmanship can coexist and thrive in the 21st century. You can explore the entire collection and find the perfect piece for you in the decorative armours catalogue.