A blade that cuts and does not bend is the voice of whoever forged it. What makes a sword a combat tool and not a mere ornament? In this article, you will discover what makes a sword truly functional, how to measure its quality, what materials and treatments matter, and which historical models are best suited for reenactment and training.

What you will learn:

- Why the tang, steel, and tempering determine the blade’s behavior.

- How to interpret the Rockwell scale and choose the appropriate hardness for use.

- Which historical types are most in demand and what to expect from each.

Historical and Technical Evolution of Functional Swords

Before discussing steels and measurements, it is worth tracing the path that led the blade from primitive forging to modern techniques. This chronology summarizes the milestones that shaped the functionality of swords.

| Epoch | Event |

|---|---|

| Ancient Periods and Primitive Forging (3rd Century B.C. – 10th Century A.D.) | |

| 3rd Century B.C. | The Romans adopt the gladius hispaniensis from the Iberian Celts. The Celts already used pattern welding techniques around 100 B.C. |

| 2nd Century – 3rd Century A.D. | Development of the spatha (Roman cavalry swords), long and slender, with steel blades that often incorporated pattern welding. |

| c. 300 A.D. | Pattern welding consolidates as a routine technique: forging and welding pieces of carburized and non-carburized iron to achieve tenacious cores and hard edges, controlling mechanical properties through the composition and arrangement of layers. |

| 300 A.D. – 586 A.D. (Migration Period) | Swords derived from the spatha spread throughout Europe. Example: Merovingian blades that preserve pattern welding techniques. |

| 650–700 A.D. | Merovingian blade from Finland built with pattern welding: two low-carbon steels twisted in the center and enclosed by folded steels (ductile core and harder edges). |

| 8th Century | Development of Viking and Carolingian swords from the Merovingian design, maintaining the search for balance between edge and toughness. |

| 9th Century | Existence of typified swords in collections and findings (e.g., specimens cataloged as from the 9th century), evidencing technical and stylistic continuity. |

| Transition and High Middle Ages (10th Century – 12th Century) | |

| Late 10th Century | Pattern welding technique largely disappears. Blacksmiths learn to refine steel and forge blades from a single bar or through rolling/stacking procedures. |

| From the 10th Century | Diffusion of the rolling procedure (layer forging/laminating), which allows combining different hardnesses without the complexity of the welded pattern. |

| 10th–11th Centuries (900 – 1130 A.D.) | Period corresponding to Type X in Oakeshott’s typology: one-handed lordly swords, designed primarily for cutting, used from horseback against light armor. |

| 12th Century | Metallurgical studies show swords built with layers of steel of variable hardness, a result of expert forging aimed at optimizing hardness, flexibility, and edge in the same blade. |

| Modern Functional Characteristics and Techniques | |

| Material: Steel |

|

| Construction | Functional swords must have a full tang to withstand impacts and actual use. Forging and tempering (heat treatment) determine performance: differential tempering (hard edge + soft spine, typical of katanas) or full tempering (uniform hardness, greater overall flexibility but different behavior under abuse). |

| Edge | For combat, edges with convexity (convex bevel or “blunter apex”) are preferred, as they resist nicks better when striking against metals or hard objects, unlike extremely sharp, razor-like edges. |

What Defines a Functional Sword Today?

The essence of a functional sword is summarized in three pillars: material, construction, and heat treatment. Without these, the sword may seem authentic, but it will not be reliable in real use.

The essence of a functional sword is summarized in three pillars: material, construction, and heat treatment. Without these, the sword may seem authentic, but it will not be reliable in real use.

- Material: well-selected carbon steels.

- Construction: full tang, clean rivets, and solid assembly.

- Tempering: balanced hardness to maintain edge and prevent fractures.

The Importance of the Tang

A full tang transmits the force of the blow from the blade to the pommel without weak points. If the tang is short or poorly fixed, the joint can fail under repeated impacts.

Balance and Ergonomics

The center of gravity should be located near the guard to facilitate maneuvers. A heavy and poorly balanced sword fatigues the user and reduces precision.

Measuring Quality: Rockwell Scale and Key Factors

Hardness is measured in HRC (Rockwell). But the number alone doesn’t tell the whole story: tempering, microstructure, and design influence real performance.

| Rockwell Range (HRC) | Typical Behavior | Recommended Uses |

|---|---|---|

| 30–40 | Flexible but less wear-resistant; can be nicked by harder edges. | Basic recreational swords, pieces with light use. |

| 40–45 | Good balance between flexibility and edge retention; common in practice katanas. | Training and safe practice requiring some flexibility. |

| 45–52 | Historical level of many medieval swords: edge strength and sufficient flexibility. | Recreational combat, non-extreme cutting, and intense use. |

| 58–60 | Extremely hard and sharp edge; more fragile against lateral impacts. | Professional cutting katanas and pieces designed for competitive cutting with control. |

In addition to HRC, assess the type of temper (differential or full), the geometry of the edge (convex for greater resistance), and the quality of the assembly. A poorly tempered 1095 will be worse than a well-worked 5160.

Historical Models That Remain Functional

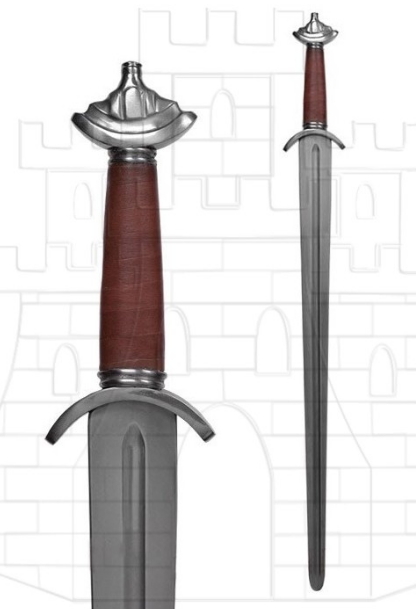

If you are looking for a replica that performs well in reenactment or training, some types are more versatile:

- Gladius: short and robust blade, ideal for thrusting and close-quarters combat.

- Viking Swords: balance between cutting and toughness.

- Medieval Swords (one-handed and hand-and-a-half, claymore): adapted to different hand-to-hand combat techniques.

- Functional Katanas: differential tempering and very efficient cutting edge.

How to Choose According to Your Use

First, consider the purpose: training, reenactment, controlled cutting, or functional collection. Each use requires a different combination of steel, hardness, and geometry.

- Training or historically safe tournaments: look for full tangs, HRC between 45–52, and convex or blunt edges for safe impact.

- Controlled cutting: steels with higher HRC and precise tempering; usually require more demanding maintenance.

- Scenic reenactment: balance between authentic appearance and safety; sometimes blunt edges or rounded tips are chosen.

Available Functional Swords

Functional Swords: Category A

Functional Swords: Category B

Functional Swords: Category C

If you are going to use the sword in practice, confirm the manufacturer’s category: classifications (SKA/SKB/SKC or internal vendor categories) indicate material quality and combat suitability.

Maintenance and Safety

A functional sword demands care: edge cleaning, corrosion protection, and inspection of the tang-blade joint after intense exercises. Always keep sharp blades out of reach of inexperienced people and use appropriate scabbards.

Clarifying Doubts About Functional and Decorative Swords

What are the main differences between functional and decorative swords?

The main differences between functional swords and decorative swords are:

- Purpose: Functional swords are designed for real use, such as training, cutting, or combat. Decorative ones are for display or collection only.

- Materials and construction: Functional ones use high-quality steel and are forged or tempered for strength and durability, with sharp and balanced blades for safe handling. Decorative ones usually have stainless steel blades or less resistant materials, without an edge, and often with simpler construction that cannot withstand strong tensions.

- Safety and resistance: Functional swords have robust blades and hilts firmly connected to withstand physical use. Decorative ones may have blades that would break under pressure and hilts that cannot withstand tension.

- Details and finishes: Decorative ones may include elaborate ornaments, engravings, and aesthetic details that are not practical for combat, while functional ones prioritize functionality and balance over decoration.

Functional swords are real tools for cutting and using, while decorative ones are visual objects designed only to look good and not for practical use.

What materials are commonly used in the manufacture of functional swords?

The materials commonly used in the manufacture of functional swords are primarily high-carbon steels, due to their hardness, resistance, and durability. Among the most used are:

The materials commonly used in the manufacture of functional swords are primarily high-carbon steels, due to their hardness, resistance, and durability. Among the most used are:

- 1045 Steel (approx. 0.45% carbon): used in basic functional swords.

- 1060 Steel (approx. 0.60% carbon): offers a good balance between hardness, flexibility, and impact resistance.

- 1095 Steel (approx. 0.95% carbon): provides very hard and sharp blades, although it can be more fragile if not properly tempered.

Damascus steel is also frequently used for functional swords, known for its strength and distinctive patterns, achieving a balance between hardness and flexibility with a carbon content of around 0.60-0.70%.

Other materials, such as stainless steel (grades 420 and 440), are more common in decorative swords, as they do not offer the mechanical properties necessary for a functional sword. The handle is generally made of noble woods, but the main material of the blade is always a steel suitable for functional tempering and forging.

How is the quality of a functional sword measured?

The quality of a functional sword is measured primarily by its precise manufacture and the materials used, as well as by the blade’s balance, hardness, and resistance. Key criteria include:

The quality of a functional sword is measured primarily by its precise manufacture and the materials used, as well as by the blade’s balance, hardness, and resistance. Key criteria include:

- Blade Material: Generally high-quality steel with an adequate carbon content that balances hardness and flexibility to prevent it from breaking or bending excessively.

- Hardness: Measured on the Rockwell scale (HRC), with a minimum recommended around 50 HRC for good wear resistance without losing flexibility.

- Balance and Weight: The sword must have an appropriate center of gravity for optimal maneuverability, frequently near the guard.

- Construction: The tang (internal part of the blade approved for the hilt) must be long and solidly fixed to ensure stability; welds must be clean and the blade polished and uniform.

- Safety: For demonstration use, the blade usually has blunt edges and a rounded tip, maintaining adequate flexibility and hardness to absorb impacts without deforming.

- Professional Categories: Functional swords are usually classified according to their resistance and material quality, with categories indicating whether they are suitable for professional or recreational practices.

The quality of a functional sword is defined by these technical and manufacturing factors, along with resistance and balance tests in simulated combat.

What characteristics must a sword have to be considered “battle ready”?

A sword to be considered “battle ready” must primarily have a tempered and hardened high-carbon steel blade, be full tang to ensure strength and durability in hand-to-hand combat, and be balanced to facilitate its handling. In addition, it usually has blunt edges and a rounded tip for safety in training or competitions, although it can sometimes be sharpened if it is for real combat. It also lacks superficial decorations or decorative elements that do not provide functionality, and can be manufactured with regulatory measurements and weights adapted to historical combat or reenactment norms. The hilt must be ergonomic for a secure and firm grip. These characteristics ensure that the sword withstands demanding use in combat without damage or risk to the user.

What types of functional swords are most popular among historical reenactment enthusiasts?

The most popular types of functional swords among historical reenactment enthusiasts are primarily medieval swords (such as the Claymore and the English infantry Falchion), Viking swords, and functional katanas. These swords are made of tempered carbon steel, offering a balance between hardness and flexibility that allows their use in scenic combat, practices, or historical reenactments. Functional swords of different eras and styles are also popular, including historical replicas based on archaeological finds and European and Japanese-style swords adapted to the user’s interest.

The most popular types of functional swords among historical reenactment enthusiasts are primarily medieval swords (such as the Claymore and the English infantry Falchion), Viking swords, and functional katanas. These swords are made of tempered carbon steel, offering a balance between hardness and flexibility that allows their use in scenic combat, practices, or historical reenactments. Functional swords of different eras and styles are also popular, including historical replicas based on archaeological finds and European and Japanese-style swords adapted to the user’s interest.

For historical reenactment, the most demanded models are:

- European medieval swords (Claymore, Falchion, classic medieval swords)

- Functional Viking swords

- Functional Japanese-style katanas

| Type | Blade Length (approx.) | Epoch | Tactical Use |

|---|---|---|---|

| Hispaniensis | 60–68 cm | 3rd–1st Centuries B.C. | Versatile: powerful cuts and thrusts in closed formations. |

- Hispaniensis

-

- Blade Length: 60–68 cm (approx.)

- Epoch: 3rd–1st Centuries B.C.

- Tactical Use: Versatile: powerful cuts and thrusts in closed formations.

Even the best carbon steel suffers wear with use. A nicked blade is not a failure: it is a witness to battles and practices. Keep the sword clean, oiled when necessary, and inspect the tang-blade joint after intense exercises.

The ideal functional sword exists: it is the one that responds to your purpose, is well-built, and respects the laws of historical and modern metallurgy. Choose wisely, care for the blade, and let history live on in every cut and every test.

FUNCTIONAL SWORDS AND SABERS | FUNCTIONAL SWORDS CATEGORY A | FUNCTIONAL SWORDS CATEGORY B | FUNCTIONAL SWORDS CATEGORY C