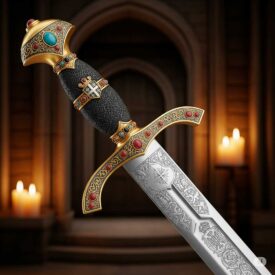

Have you ever felt the weight of history holding a sword? That blade doesn’t just hold metal; it holds battles, journeys, and hands that have touched it. Keeping it in perfect condition is as much an act of respect as it is a practical necessity. In this article, you will learn proven techniques, recommended products, and routines that preserve the functionality and aesthetics of your sword, from blade to hilt.

Why Maintenance is Essential

A neglected sword loses its defensive capability and beauty. Steel can rust, wood or leather hilts crack, and small looseness can turn into structural failures. Proper maintenance prolongs its lifespan, avoids costly repairs, and keeps the piece safe for display or historical practice.

The difference between a shiny blade and one covered in stains can be a simple routine gesture: cleaning fingerprints, oiling the surface, and checking the fit of the guard. These gestures are the first line of defense against corrosion and wear.

Brief Chronology of Sword Care

The care of weapons has evolved with metallurgy. In ancient times, animal fats and waxes were used to protect metal; in the Middle Ages, oils and manual polishing gained importance; with the industrial age came refined oils and more advanced protection techniques. Today, we combine traditional knowledge with specialized products to achieve the best preservation.

| Period | Protection Method | Comment |

|---|---|---|

| Antiquity | Animal fats and waxes | Basic protection; easy availability of natural materials. |

| Middle Ages | Polishing and domestic oils | Regular maintenance appears in workshops and arsenals. |

| Modern Age | Refined oils and tempering techniques | Better understanding of metal and more durable treatments. |

| Contemporary Era | Specialized oils, waxes, and coatings | Combination of tradition and modern chemistry for long-term preservation. |

- Antiquity

-

- Method: Animal fats and waxes

- Comment: Basic protection with natural materials.

- Middle Ages

-

- Method: Polishing and domestic oils

- Comment: Frequent maintenance in workshops and arsenals.

Fundamental Principles of Cleaning

Regular cleaning: After use, dry and clean the blade with a soft cloth to remove dust, sweat, and residue. Sweat contains salts and acids that attack metal; avoid touching the blade with bare hands whenever possible.

Regular cleaning: After use, dry and clean the blade with a soft cloth to remove dust, sweat, and residue. Sweat contains salts and acids that attack metal; avoid touching the blade with bare hands whenever possible.

Avoid aggressive abrasives: Do not use coarse steel wool or corrosive chemicals without knowledge, as they can alter the temper or finish. When rust needs to be removed, proceed carefully with appropriate products or seek professional help.

Recommended Products and Tools

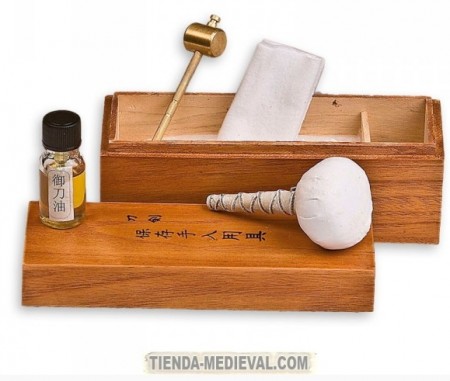

On the market, there are specific kits and oils for swords, sabers, and katanas. These kits usually include components designed for the type of sword: from fine non-abrasive powders to cotton cloths and low-residue oils. Using the right product reduces the risk of damage.

Among the most useful items are: microfiber or cotton cloths, camellia or mineral oils, uchiko powder for katanas, rice papers for traditional cleaning, and small brushes for hilts. To sharpen the edge, there are sharpeners and stones that allow restoring the bevel with control.

Lubricants for swords

Sharpeners for swords and knives

Tools for cleaning katanas

Oils and Lubricants: Correct Choice

The choice of oil is crucial. Camellia oil and pure mineral oil are classic references for their stability and protection. Lithium grease is reserved for prolonged storage when a denser layer is needed.

| Product | Advantages | Recommended Use |

|---|---|---|

| Camellia oil | Natural, non-volatile, protects without sticky residue | Regular protection and after cleaning |

| Pure mineral oil | Stable, does not degrade quickly | Periodic maintenance and short-to-medium term protection |

| Lithium grease | Dense and durable layer | Long-term storage in dry environments |

| Carnauba wax | Shine and physical barrier | Decorative finishes and additional protection |

- Camellia oil

-

- Advantage: Non-volatile and non-reactive

- Use: Protection after cleaning

- Pure mineral oil

-

- Advantage: Durable

- Use: Regular maintenance

How to Oil and Clean Step by Step

1. Initial cleaning: With a soft cloth, remove dust and dirt. If there are stubborn residues, use rice paper (in the case of katanas) or a mild, non-abrasive solution applied carefully.

2. Removing light rust: Use uchiko powder or a non-aggressive cleaner, rubbing with gentle movements and always following the grain of the blade. Avoid sandpaper or coarse scourers.

3. Applying oil: Apply a few drops of oil onto a clean cloth and wipe it over the entire blade. Do not use excessive amounts; the idea is to create a thin protective layer.

4. Hilt inspection: Clean the hilt according to its material: damp cloth for wood followed by linseed oil, moisturizing cream or specific grease for leather, and lubrication with fine oil for metal parts.

Detecting and Treating Rust: Precautions

Inspect every six months. If you find superficial rust spots, act calmly. For small stains, mix baking soda with water to form a soft paste or use a specialized product. More aggressive chemical or mechanical techniques require expertise to avoid damaging the temper or finish.

Inspect every six months. If you find superficial rust spots, act calmly. For small stains, mix baking soda with water to form a soft paste or use a specialized product. More aggressive chemical or mechanical techniques require expertise to avoid damaging the temper or finish.

Recommendation: in case of advanced rust or doubts, consult a conservator or specialized armorer. Incorrect intervention can lead to material loss or irreparable aesthetic damage.

Hilt Maintenance: Wood, Leather, and Metal

The blade demands attention, but the hilt deserves the same dedication. A damaged hilt compromises the grip and the weapon’s safety. Here, cleaning and treatment vary according to the material.

Wooden Hilt

Clean with a damp cloth and dry quickly. Apply linseed oil or specific wood oils to prevent it from drying out and cracking. Avoid products with alcohols that dry out the wood.

Leather Hilt

Leather requires periodic hydration with leather creams or oils to maintain its flexibility. Do not use raw vegetable oils that become rancid and attract dirt.

Metal or Synthetic Hilt

Clean it like the blade and apply a light coat of oil to the metal areas. Check screws or rivets and tighten carefully if you notice any looseness.

Comparative Table: Materials and Susceptibility to Rust

| Material | Rust Resistance | Maintenance Recommendation |

|---|---|---|

| Chrome-alloyed steels (e.g., 5160) | High | Periodic cleaning and preventive oil |

| Unalloyed carbon steels | Low – medium | Frequent oiling and dry storage |

| Stainless steels | High | Light maintenance: clean and protect |

- Chrome-alloyed steels

-

- Resistance: High

- Maintenance: Cleaning and preventive oil

Inspection and Preventive Maintenance: Recommended Routines

Establish a routine: visual check every month if you use it frequently, and a thorough inspection every six months. Observe points of oxidation, looseness in the guard, coating degradation, and the condition of the hilt.

-

Every use: Quick cleaning and drying.

-

Every 3-6 months: Complete cleaning, gentle polishing, and oil application.

-

Every year: Deep structural review and component adjustment.

Restoration and Rust Removal: Methods and Risks

There are three approaches: chemical, mechanical, and manual. Chemical uses reagents that dissolve rust; mechanical uses abrasives; and manual combines soft tools and specific products. The biggest risk is removing healthy material or damaging the temper. Proceed with fine abrasive tools and consult if the piece has historical or sentimental value.

Clarifying Doubts About Sword Care and Maintenance

What are the best oils for sword maintenance?

The best oils for sword maintenance are pure mineral oil and camellia oil. Mineral oil is ideal for its high penetration, cleanliness, and durability, without forming residues that attract dirt, especially recommended for regular protection. Camellia oil, being natural, acid-free, and non-volatile, is widely used for oxidation protection and lubrication, especially for carbon steel swords and tools.

Additionally, for prolonged storage, lithium grease is recommended because it does not evaporate quickly and protects the metal well, although it can attract dirt and give a messier appearance.

Types of Oil and Their Characteristics for Maintenance

Caring for tools, home, or any object that needs to be greased or lubricated requires knowledge about what type of lubricant is appropriate. Below, we detail the most commonly used types of oil and their applications.

| Type of Oil | Main Characteristics | Recommended Use |

|---|---|---|

| Mineral oil | High penetration, does not degrade or attract dirt | Regular protection and maintenance |

| Camellia oil | Natural, acid-free, non-volatile | Antioxidant protection, lubrication |

| Lithium grease | Dense, durable, does not evaporate | Long-term storage, protection |

Conventional vegetable oils should be avoided as they can degrade and cause dirt accumulation. For good maintenance, apply and renew regularly according to use and conditions.

How does improper storage affect the sword?

Improper storage negatively affects the sword mainly because it promotes rust and corrosion, damages materials, and can cause deformation. Storing the sword in humid environments, in leather scabbards or cloth covers that retain moisture, or exposing it to direct sunlight causes deterioration of the blade and components such as the wood and leather of the handle. Furthermore, variable temperatures and humidity generate stress in the sword, affecting its shape and strength. To avoid these damages, the sword should be stored in a dry place, with constant temperature and humidity, preferably horizontally or slightly tilted, and with the blade regularly oiled to protect it from corrosion. It is also advisable to use padded supports to avoid mechanical stress.

Improper storage negatively affects the sword mainly because it promotes rust and corrosion, damages materials, and can cause deformation. Storing the sword in humid environments, in leather scabbards or cloth covers that retain moisture, or exposing it to direct sunlight causes deterioration of the blade and components such as the wood and leather of the handle. Furthermore, variable temperatures and humidity generate stress in the sword, affecting its shape and strength. To avoid these damages, the sword should be stored in a dry place, with constant temperature and humidity, preferably horizontally or slightly tilted, and with the blade regularly oiled to protect it from corrosion. It is also advisable to use padded supports to avoid mechanical stress.

What techniques exist to prevent corrosion in swords?

The main techniques to prevent corrosion in swords are:

- Keep the blade dry and clean, eliminating moisture, dust, dirt, and residues like fingerprints that accelerate oxidation. Frequent cleaning and inspection are recommended, at least every three to six months.

- Apply protective oils or waxes, such as mineral oil, gun oil, carnauba waxes, or special conservation waxes that form an impermeable layer and prevent metal contact with moisture.

- Use protective coatings that act as physical barriers (paints, polymeric films, or primers) to prevent oxygen and water from reaching the metal, especially increasing protection in aggressive environments.

- Employ cathodic protection, which consists of converting the metal into a cathode to prevent its oxidation by joining it with a more reactive sacrificial anode, although this technique is more common in underground or submerged structures.

- Avoid electrical contact between different metals and design with appropriate materials to minimize corrosion due to cracks or concentrated mechanical stresses.

These combined methods allow effective protection against corrosion in swords, extending their useful life and maintaining their integrity.

How should a sword hilt be cleaned?

The hilt of a sword should be cleaned with a soft, slightly dampened cloth, avoiding water accumulation to prevent damage to materials like wood or leather. For wooden hilts, after cleaning with the damp cloth, it is important to dry thoroughly and regularly apply special oil or linseed oil to prevent it from drying out or cracking. For leather hilts, it is recommended to remove dust with a soft brush, clean with a specific leather spray if necessary, and apply grease or oil to maintain its flexibility. In the case of metal hilts, clean them like the blade and it is advisable to protect them with a thin layer of oil to prevent oxidation. The hilt should never be submerged in water or allowed for moisture to penetrate the joints with the blade, to prevent corrosion or material deterioration.

- Use a soft, slightly damp cloth, avoid excess water.

- Wood: clean and dry well, apply linseed oil regularly.

- Leather: brush off dust, clean with leather spray and grease or oil.

- Metal: clean similar to the blade, protect with fine oil.

- Do not submerge or over-wet, nor allow water to accumulate in joints.

What materials are most resistant to rust in swords?

The most rust-resistant materials in swords are alloyed steels with a high chromium content, as these elements increase corrosion resistance. For example, steels like 5160, which contain carbon and chromium, are preferred for sword making due to their high impact resistance and greater protection against oxidation compared to simple carbon steels. Furthermore, highly alloyed steels tend to be more rust-resistant than low-alloy steels.

- Chrome-alloyed steels (like 5160) are more rust-resistant.

- Carbon steels without additional alloys are more prone to rapid rusting.

Chromium content creates a passive layer of chromium oxide that protects the base metal from deterioration, which does not occur in unalloyed or low-alloy steels. It is also important to consider proper maintenance to prevent corrosion.

Although aluminum is known for its rust resistance, it is not a typical material for swords due to its different mechanical properties.

Therefore, for swords, chromium-alloyed steels are preferred for greater rust resistance.

Final Tips for Keeping the Blade Alive

Maintenance is a ritual that connects the custodian with the history of the weapon. Observe, clean, and protect consistently. Value every small sign of wear as an opportunity to intervene before the damage is irreversible. With the practices described here, your sword will be able to maintain its shine and functionality generation after generation.

VIEW SHARPENERS | VIEW KATANA CLEANING KITS | VIEW LUBRICANTS FOR SWORDS