Toledo and its swords form an inseparable pair: when historic bladed weapons are discussed, the name of this city appears immediately. The Toledo swords are not just beautiful objects; they are the result of centuries of experimentation, tradition and applied science to metal.

A legend forged in metal

The history surrounding the swords of Toledo is both cultural and technical. From the earliest pieces produced in the Bronze Age to the blades that became a symbol of military elite, Toledan steel has been admired for its ability to combine edge, hardness and resilience. In this section we explore its origins and how Toledo’s reputation was consolidated over the centuries.

Historical roots: Metallurgy in Toledo dates back to remote times. As early as 192 BC, with the Roman conquest of the oppidum that would become Toletum, the quality of locally forged iron was noted. Legends such as that of Hannibal and the Celtiberian falcatas reveal a chain of metallurgical knowledge that endured through Roman, Visigothic, Arab and Christian influence.

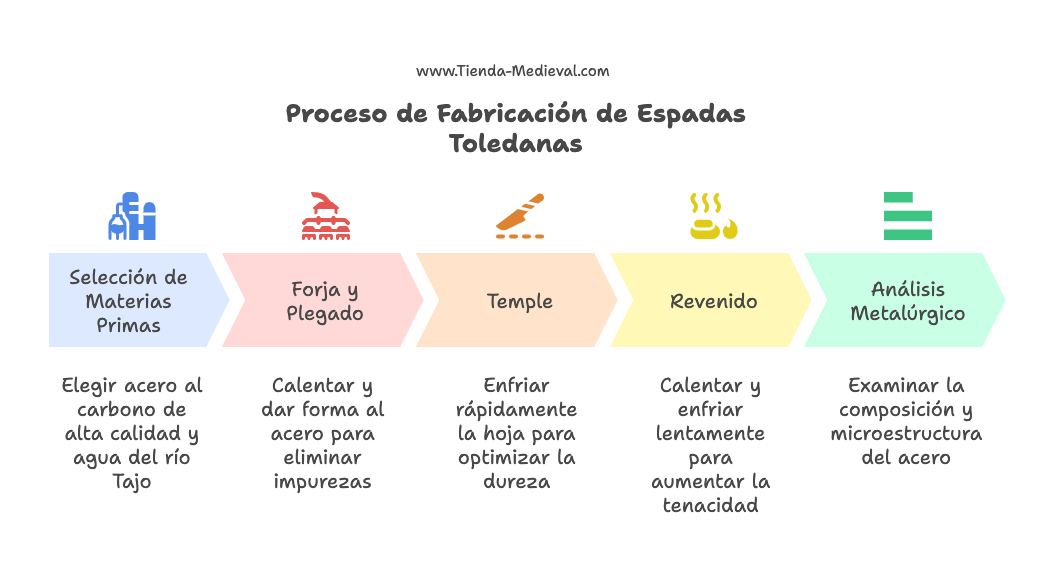

How a blade becomes a legend: the traditional process

The manufacture of a classic Toledan sword combines materials, techniques and controlled timing. It is not just brute force, but precision. Below we break down the key stages that defined and still define the swords of Toledo.

Raw materials: the basis of character

Traditionally the blades were worked with carbon steel derived from local ores and charcoal from selected woods. The base iron, combined with strict carbon control, marks the difference between an ordinary blade and a Toledan piece. Legend adds that water from the Tagus influenced the quench; today we know factors such as chemical composition and heat treatment are the main determinants.

Forging and folding: purification and structure

The forging process includes heating the steel to specific points (the swordsmith recognizes colors from pale red to cherry red) and hammering it repeatedly. Multiple folding and forging allow impurities to be removed and the alloy to be homogenized, improving the grain structure. This produces a blade that combines hardness and flexibility: essential for withstanding the battlefield.

The quench: the critical moment

Quenching is the treatment that defines much of the mechanical behavior of steel. It consists of heating the blade to controlled temperatures and cooling it quickly. Historically media such as Tagus water or traditional oils were used; today oil is often used because its more gradual effect reduces fractures. Quenching optimizes hardness; many modern replicas reach between 50 and 55 HRC on the Rockwell scale.

Tempering: balance between hardness and toughness

After quenching comes tempering, heating the blade to lower temperatures (approx. 260–300°C) to relieve internal stresses. This step increases toughness and prevents extreme hardness from making the blade brittle. The result is a sword capable of holding an edge without breaking under impact.

Microstructure and chemistry

Metallographic analyses show varied phases and a complex grain size in historical blades. Elements such as carbon, manganese, silicon, nickel and chromium appear in different proportions. Even traces of vanadium or tungsten could influence the structure, improving the final mechanical behavior.

Characteristics that made Toledan swords unique

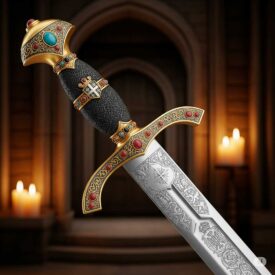

Toledan swords were identified by a set of mechanical and aesthetic qualities that distinguished them from other European blades.

- Hardness and edge: Able to keep an extremely sharp edge without losing integrity.

- Toughness: Resistance to fracture upon impact, thanks to well-executed tempering and quenching.

- Corrosion resistance: Which caused many blades to survive to this day in surprisingly good condition.

- Finish and decoration: Polished surfaces, engravings and, on occasion, damascening on grips and guards.

Toledo versus Damascus: two schools, two spirits

Toledan steel and Damascus steel represent two pinnacles of historical metallurgy. Both share techniques such as folding and forging, but differ in raw materials and aesthetics.

Similarities

Both Toledo and Damascus used forging and folding to combine hardness and flexibility. Both processes required master smiths with thermal sensitivity and the skill to detect the exact working point.

Differences

Damascus steel often derives from Wootz steel with wavy patterns visible after etching, while Toledan swords were distinguished by a smoother surface and decorations on guards and grips. Materially, the origins of the ores were different: local ores in Toledo versus imported materials in the case of Wootz steel.

In performance, there has been debate about which was superior: many historical sources consider Toledan swords to have been somewhat harder, while Damascus blades stood out for balancing hardness and elasticity. Today, researchers and modern smiths continue comparing microstructures to understand why both steels endured as references.

The rapier: elegance and functionality

Among the most famous pieces made in Toledo is the rapier, also known as the rapier. Popular since the 16th century, this weapon evolved from broad blades to long, straight and narrow blades designed for fencing and dueling. Its hilt evolved into increasingly protective guards, passing through ring, shell and cup styles.

The rapier imposed a social and military style: it was a ceremonial weapon, for urban personal defense and a status symbol for nobles and officers. In literature and history it is associated with figures such as Don Quixote, tercio captains and conquistadors.

From splendor to industrialization and its preservation

The arrival of firearms transformed the demand for swords. To protect a craft that was part of the national heritage, Charles III created in 1761 the Real Fábrica Nacional de Armas in Toledo, the work of Francisco Sabatini. The factory protected master craftsmen and standardized processes for centuries, until its closure in 1996. Its technical and human legacy remains present in modern workshops.

Today’s craftsmen: keeping the flame alive

Today forging in Toledo is sustained thanks to independent workshops and masters who have inherited century-old techniques. Contemporary figures like Antonio Arellano and Mariano Zamorano are examples of this continuity. Although competition with mass production is a challenge, demand for historical pieces for film, television and theme parks has created new opportunities.

Modern craftsmen combine tradition and science: they apply metallographic tests, modern anti-corrosion treatments and thermal control tools without losing the manual forging techniques that make each sword unique.

How to recognize an authentic Toledan sword

Identifying an authentic piece requires attention to technical details and provenance evidence.

- Mark of origin: The mark Hecho en Toledo or workshop stamps certified by local associations provide reliability.

- Finish and weight: A real Toledan blade shows a polished finish and balanced weight; it should not feel unbalanced or excessively light.

- Microstructure and tests: Metallographic analyses and hardness tests confirm compositions and heat treatments typical of the craft.

- Documentation: Certificates, provenance and the artisan’s or workshop’s warranty support authenticity.

Preserving and caring for a Toledan sword

A well-cared-for sword can last centuries. Practical recommendations:

- Clean the blade with soft cloths after handling to avoid stains from sweat or moisture.

- Apply protective oil periodically to prevent corrosion.

- Avoid storage in humid environments or in sheaths that retain moisture.

- If the blade has decoration or gilding, consult the workshop about specific cleaning products.

Where to buy and what to expect when looking for Toledo swords

If you are interested in acquiring an authentic Toledan sword, we recommend comparing provenances and opting for pieces with certification. For those who prefer the security of a verified purchase, it is advisable to do so in our online store, where we guarantee the origin and quality of each product.

Buying tips:

- Look for information about the artisan or brand and ask for a guarantee of authenticity.

- Check the type of steel and the heat treatment if you need a functional piece and not just a decorative one.

- Value pieces with documentation and the possibility of returns or certificates of authenticity.

Acquiring a Toledan sword is an investment in a fragment of history: its value is not only aesthetic but also cultural and technical.

Toledo as a destination: what to see for steel lovers

Visiting Toledo is an experience for the senses. Strolling its narrow streets, contemplating the Tagus, and stopping at workshops and museums related to forging are must-do activities for those who love the history of weapons and craftsmanship.

Points of interest include workshops of local craftsmen, museums with collections of historical weapons and exhibits on traditional processes. The city’s cultural triangle — Christian, Jewish and Arab — provides a historical context that explains the richness of its metallurgy.

Legacy and influence on modern metallurgy

The study of Toledan swords has influenced current metallurgy. Techniques such as folding, the selection of alloying elements and thermal control are applied today in the manufacture of high-end knives and tools. In some cases, modern replicas outperform originals in corrosion resistance thanks to current treatments, although the historical value remains irreplaceable.

Today, traditional knowledge coexists with modern testing that allows understanding and replicating the properties of historical blades, offering functional and aesthetically faithful pieces.

Why a Toledan sword still moves people

Toledan swords move people because they sum up technique, beauty and memory. They are objects that tell stories: of battles, of crafts passed down through generations, and of man’s relationship with materials. Owning a Toledan sword is to connect with a tradition that has survived technological and social changes.

If you are looking for a piece as a collectible, for historical setting or as a gift, a Toledan sword offers aesthetic and technical assurance. Remember that buying in our online store gives you the security of acquiring an item with provenance and warranty.

SEE MARTO SWORDS | SEE J.L. RUBIO SWORDS | SEE ART GLADIUS SWORDS | SEE BERMEJO SABRES